Our in-house compounding line allows us to precisely formulate rubber blends to suit diverse application stresses—pressure, temperature, chemical exposure, and longevity. We process:

AFC

Rubber Compounding

Each compound is engineered with specific requirements of customers in mind, enabling performance in water contact, food contact, and environmentally sensitive applications.

AFC

Moulding Technologies

Versatility in moulding is what enables us to serve different industries without compromise.

Compression Moulding

Ideal for standard parts with high-strength and robust dimensional tolerances.

Vacuum Compression Moulding

Enables ultra-clean finishes, zero flash lines, and high repeatability.

Injection & Transfer Moulding

Supports complex geometries, tight tolerances, and high-volume demands where precision can’t be compromised.

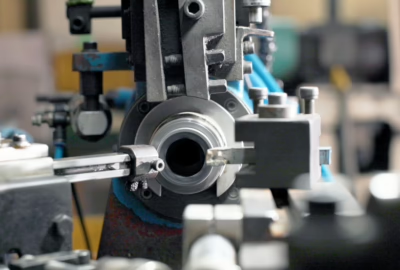

Metal-to-Rubber Bonding

At the heart of many of our flagship products lies one key strength metal to rubber adhesion.

Our expertise in this highly specialised process powers components where mechanical integrity and sealing performance are equally critical. Every bonded part undergoes controlled pre-treatment, adhesive application, and post-moulding validation to ensure faultless fusion.

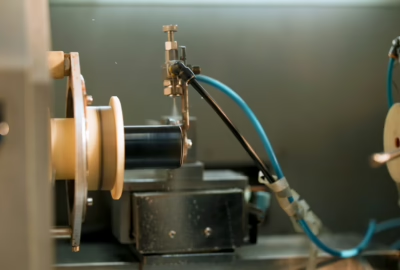

Automated Deflashing, Trimming & Grinding

Precision doesn’t stop at moulding. Our post moulding operations feature:

- Automated deflashing for flash / burr free edges

- High speed trimming for dimensional uniformity

- Centreless & cylindrical grinding for close tolerance and controlling the run-out / concentricity

These operations are designed to maintain part integrity, reduce manual error, and deliver components ready for line-fit or assembly.

AT

AFC Elastomers Technology Pvt. Ltd.

Established in 1974, AFC Elastomers has evolved into a leading global manufacturer and exporter of precision rubber molded and rubber‑to‑metal bonded components. Today, AFC’s expert solutions power industries as diverse as Gas Regulator & Meter, Valves, Submersible Pump, Bearings (Industrial & Automotive) and other customized Industrial applications.