A journey of precision, purpose and progress since 1974.

PASSION

Milestones That Moulded Us

STORY

A Journey of Excellence through Perseverance

STORY

1974

Born as a specialist in rubber parts for pumps and gas regulators.

STORY

1980s–1990s

Expanded capabilities to include rubber to metal bonded components for heavy industrial uses.

STORY

2000

Introduced FDA grade rubber compounds for water and food contact applications.

STORY

2008

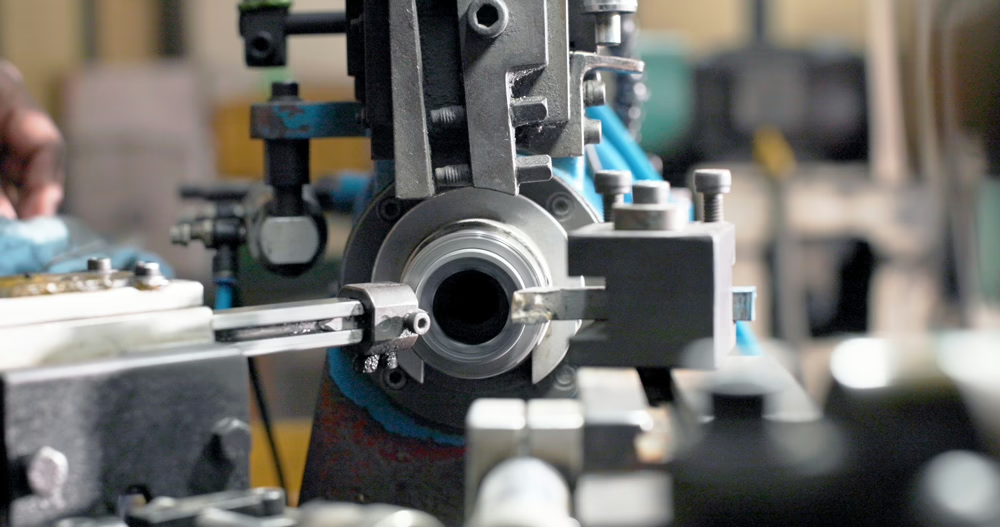

Introduce Injection & Vaccum Compression Molding process with highly precision tear trim molds along with automated de flashing process thereby eliminating the process of manual intervention.

STORY

2015

Integrated and State of an art manufacturing Facilities of more than 150K sq. feet under one Roof with Automation Facilities.

STORY

2023

Successfully implementation of IATF 16949 certification.

STORY

Today

A trusted global supplier with FDA, ROHs and REACH certified rubber molded and rubber to metal components to the world.

Leading with Precision. Recognised for Reliability.

Today, we stand as a precision rubber parts supplier to over 45 global OEMs. But this is not the destination it’s a continuation of a journey fuelled by material science, customer confidence and a relentless belief in building better, smarter, and more sustainable solutions.

Our Unique Workspace & Team

AFC Elastomers Technology Pvt. Ltd.

Founded in 1974, AFC Elastomers Technology Pvt. Ltd. is a global manufacturer and exporter of precision rubber molded and rubber-to-metal bonded components. The company provides end-to-end engineering solutions, from custom compound formulation and tool design to various molding techniques and automated inspection.